Laser Engraving Machine Buyer’s Guide: How to Choose a Reliable, Precise, and Cost-Effective System That Delivers Real Value

A laser engraving machine is far more than a tool—it’s a gateway to precision craftsmanship, scalable production, and creative freedom. Whether you’re a hobbyist personalizing gifts, a small business owner crafting custom merchandise, or an industrial user integrating automation into manufacturing, the right laser system can dramatically boost efficiency, quality, and profitability. With options ranging from CO₂ to fiber lasers, and power levels from 30W to over 100W, choosing the right machine involves balancing material compatibility, engraving speed, software integration, safety, and—critically—cost. This guide cuts through the marketing noise to help you select a laser engraving machine that offers genuine long-term value, with a dedicated deep dive into pricing so you invest wisely without overpaying.

Types of Laser Engraving Machines: Technologies, Materials, and Applications

Laser engraving machines utilize different technologies, each suited for specific materials and applications. Understanding these distinctions is crucial for selecting the right system. CO2 lasers are versatile, capable of engraving and cutting organic materials like wood, acrylic, leather, fabric, glass, and certain plastics. They operate by generating a beam of light within a CO2 gas mixture, which is then directed to the material surface. Their power output typically ranges from 30W to 150W or more, influencing speed and depth.

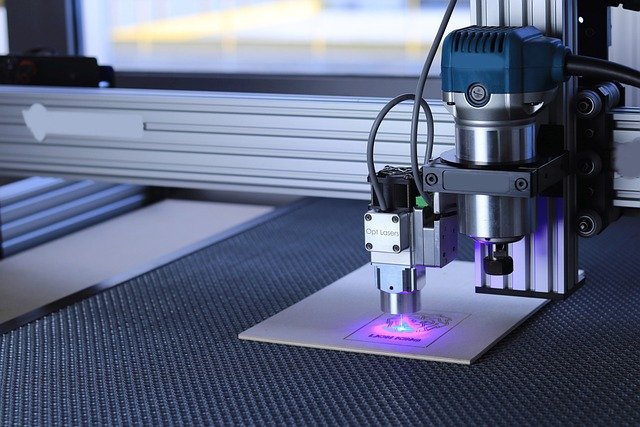

Fiber lasers, on the other hand, are highly effective for marking metals, certain plastics, and composites. They produce a high-intensity beam within an optical fiber, offering superior precision and speed for intricate designs on hard surfaces. Fiber lasers are often used for industrial applications, product serialization, and detailed jewelry engraving. Diode lasers represent a more entry-level option, often found in smaller, more affordable machines. They are suitable for engraving softer materials like wood, leather, and some plastics, but typically have lower power and slower speeds compared to CO2 or fiber lasers, making them ideal for hobbyists or small-scale projects.

Performance & Precision: What Truly Defines a High-Quality Laser System

The quality of a laser engraving system is determined by several key performance indicators beyond just its type. Precision, for instance, is influenced by factors such as the machine’s resolution, often measured in dots per inch (DPI), which dictates the level of detail achievable in an engraving. Higher DPI allows for sharper images and finer lines. The consistency of the laser beam, known as beam quality, also plays a significant role, ensuring uniform engraving depth and clarity across the work area. A stable beam minimizes distortions and produces repeatable results.

Speed and power are interlinked characteristics. While higher power (measured in watts) generally allows for faster engraving or deeper cuts, the machine’s motion system and software also contribute to overall operational speed without compromising accuracy. Repeatability, or the ability of the machine to return to the exact same position for subsequent passes, is vital for multi-pass engravings or when creating identical items. A robust frame and high-quality stepper motors or servo systems contribute significantly to both precision and repeatability, ensuring the laser head moves accurately and consistently.

Laser Engraving Machine Pricing Breakdown: What You’re Really Paying For

The cost of a laser engraving machine can vary widely, reflecting a combination of technology, power, build quality, and included features. Entry-level diode lasers might start from a few hundred dollars, suitable for hobbyists. Mid-range CO2 lasers, popular for small businesses and makerspaces, typically range from a few thousand to tens of thousands of dollars, depending on work area size, laser power, and brand reputation. Industrial-grade fiber lasers, designed for high-volume metal marking, can reach into the tens of thousands or even hundreds of thousands of dollars.

Beyond the initial purchase price, several factors contribute to the overall investment. These include the cost of accessories like rotary attachments for cylindrical objects, air assist systems to prevent flare-ups, and exhaust systems for fume extraction. Software licenses, replacement parts like lenses and mirrors, and consumable items such as laser tubes (for CO2 lasers) also factor into the long-term operational expenses. Additionally, warranty coverage, technical support, and training can influence the perceived value and total cost of ownership.

How to Spot a High-Value Laser Engraving Machine: A Practical Selection Checklist

Identifying a high-value laser engraving machine involves a careful assessment of its features against specific operational needs. Begin by defining your primary application: what materials will you engrave or cut, and what level of detail is required? This will help determine the appropriate laser technology and power. Consider the work area size; it should accommodate your largest anticipated projects without unnecessary excess that might increase cost and footprint.

Evaluate the machine’s build quality, looking for sturdy construction that minimizes vibrations and ensures stability during operation. User-friendly software interfaces and compatibility with common design programs are essential for a smooth workflow. Safety features, such as interlocks and emergency stop buttons, are paramount. Research the manufacturer’s reputation for reliability, customer support, and the availability of spare parts and service. A comprehensive warranty and accessible technical assistance can significantly enhance the long-term value of your investment.

Maximizing Longevity and Performance: Setup, Operation, and Maintenance Tips

Proper setup, careful operation, and regular maintenance are crucial for extending the lifespan and ensuring consistent performance of a laser engraving machine. Upon installation, ensure the machine is placed on a stable, level surface in a well-ventilated area to manage heat and fumes effectively. Connecting a robust exhaust system is vital for removing airborne particles and maintaining a safe working environment. Calibrating the laser beam and mirrors according to the manufacturer’s guidelines is also a key initial step to ensure optimal power delivery and engraving quality.

During operation, always adhere to safety protocols, including wearing appropriate eye protection and never leaving the machine unattended, especially when cutting flammable materials. Regularly clean the optical components, such as lenses and mirrors, with specialized cleaning solutions and lint-free wipes to prevent dust and debris from scattering the laser beam, which can degrade engraving quality and potentially damage components. Periodically check and tighten belts, lubricate moving parts as recommended, and keep the work area clean. Software updates from the manufacturer can also introduce performance enhancements and new features.

| Product/Service | Provider | Cost Estimation |

|---|---|---|

| K40 CO2 Laser Engraver | Various (e.g., OMTech, Vevor) | $400 - $800 |

| Glowforge Aura | Glowforge | $1,200 - $1,500 |

| OMTech 50W CO2 Laser Engraver | OMTech | $2,000 - $3,500 |

| XTool D1 Pro | XTool | $600 - $1,000 |

| Thunder Laser Nova 24 | Thunder Laser | $8,000 - $12,000 |

| Epilog Zing 16 | Epilog Laser | $10,000 - $20,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Choosing a laser engraving machine requires a thoughtful approach, balancing technological capabilities with practical needs and budget considerations. By understanding the different types of lasers, evaluating performance metrics, and factoring in the complete cost of ownership, buyers can make an informed decision. Prioritizing robust construction, user-friendly software, and reliable support alongside consistent maintenance will help ensure the chosen system delivers precision and value over its operational life. An investment in a well-suited machine can significantly enhance creative and production capabilities.