Building Resilience through Industrial Symbiosis: A New Era in Manufacturing

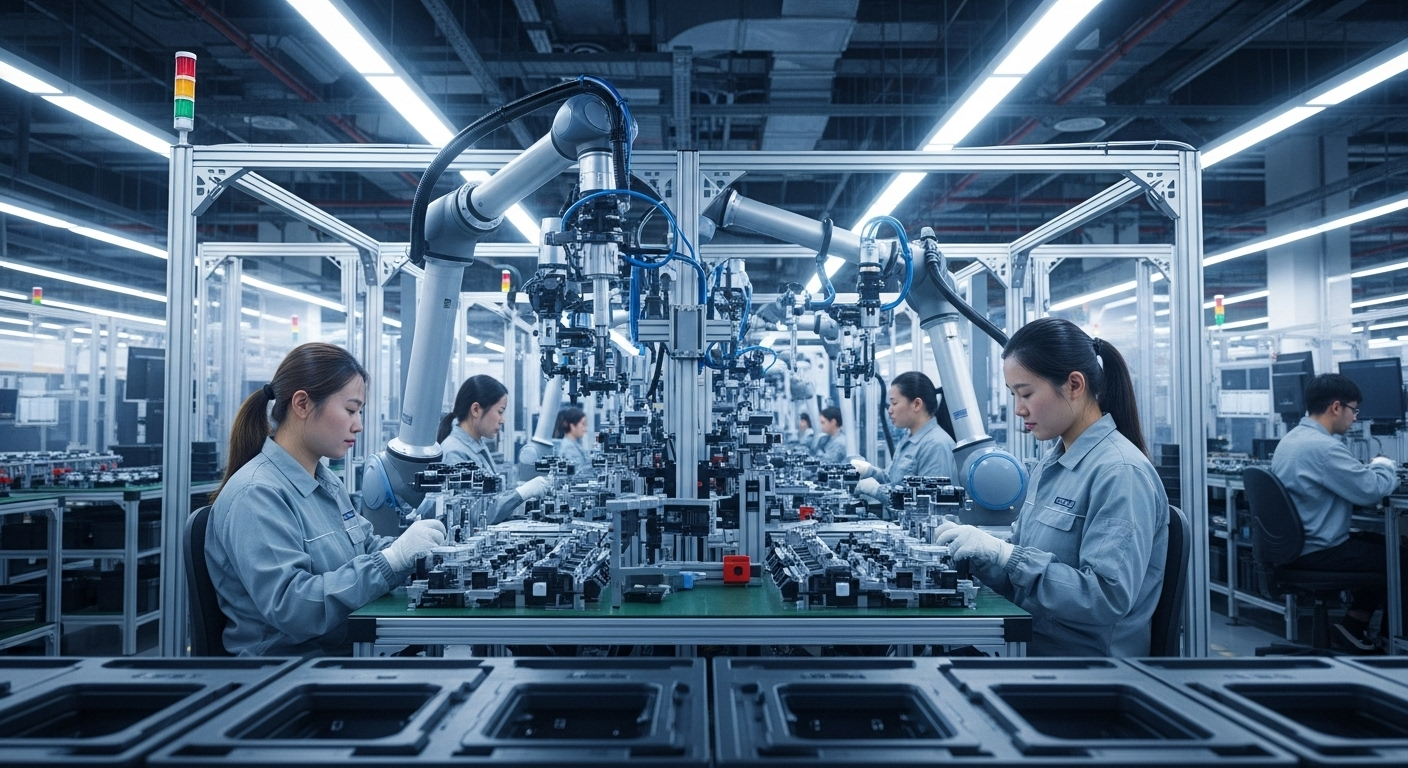

In the ever-evolving realm of industrial operations, the concept of industrial symbiosis has emerged as a promising trend. This article delves into the intricacies of this innovative approach and explores how it can bolster resilience in manufacturing, thus paving the way for a new era in business and industry.

Industrial symbiosis, a subfield of industrial ecology, emphasizes the shared use of services, utility, and by-product resources among industries to improve economic and environmental performance. This concept, originally inspired by natural ecosystems, is now gaining momentum in the industrial sphere, offering a new perspective on enhancing operational efficiency and sustainability.

In the past, industries operated in isolation, often leading to resource wastage and environmental degradation. The advent of industrial symbiosis marked a radical departure from this traditional model. It fostered a sense of interdependence among businesses, allowing them to exchange resources and collaborate on waste management, thus reducing their environmental footprint while enhancing productivity.

Today, the symbiosis model is being widely adopted in various sectors, from manufacturing and agriculture to energy and waste management. It has proven particularly effective in fostering resilience in the face of economic and environmental uncertainties, thereby setting the stage for a more sustainable and profitable future.

However, implementing industrial symbiosis is not without challenges. It requires a significant shift in mindset, along with the development of robust networks and collaborations among businesses. Furthermore, the practicality and effectiveness of this approach can vary depending on the specific industry and regional context.

Despite these challenges, the potential benefits of industrial symbiosis are substantial. It can help industries minimize waste, reduce costs, foster innovation, and enhance competitiveness. Furthermore, by promoting resource efficiency and sustainability, industrial symbiosis can play a crucial role in achieving the United Nations’ Sustainable Development Goals.

Practical Insights for Industrial Symbiosis Implementation

-

Begin with a thorough assessment of your industry’s resource flows and waste streams. Identify potential synergies and areas where resources can be shared or exchanged.

-

Foster a culture of collaboration and openness within your organization. Encourage employees to think creatively about how resources can be used more efficiently.

-

Reach out to other businesses in your region or sector. Explore opportunities for collaboration and resource exchange.

-

Consider seeking expert guidance to navigate the complexities of implementing industrial symbiosis. This can help ensure a smooth and successful transition.

In conclusion, industrial symbiosis represents a promising avenue for enhancing resilience and productivity in manufacturing. By fostering interdependence and resource sharing among industries, it can help usher in a new era of sustainable and profitable operations.

Despite the challenges involved in its implementation, the potential benefits of industrial symbiosis are substantial. With the right approach and mindset, businesses can leverage this innovative model to drive growth, enhance sustainability, and navigate the uncertainties of the future with confidence. Ultimately, industrial symbiosis could play a pivotal role in shaping the future of business and industry.